Asbestos Metallic Friction Sheet

Asbestos Metallic Friction Sheet Specification

- Features

- High Temperature Resistance, Excellent Fade Resistance, Oil-Proof, Good Frictional Coefficient, Robust Construction

- Noise Level

- Low Noise Performance

- Usage & Applications

- Used in Heavy Vehicles, Industrial Machinery, Winches, and Elevators

- Part Type

- Friction Sheet / Lining Material

- Mounting Type

- Riveted or Bonded

- Brake Type

- Drum & Disc Brakes, Multiple Applications

- Size

- 1500 mm x 500 mm (custom sizes available)

- Material

- Asbestos with Interwoven Metallic Wires

- Pattern Material

- Copper/Brass Wire Mesh Reinforcement

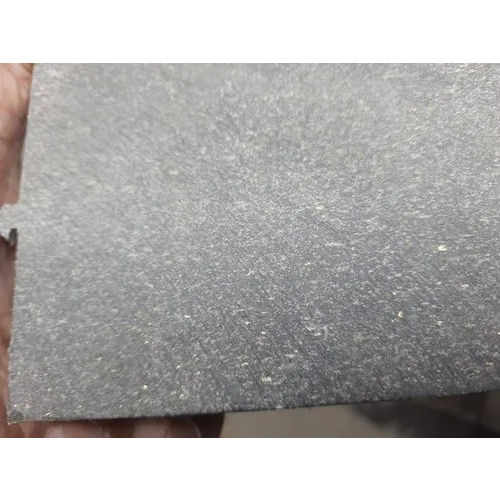

- Surface Finish

- Smooth, Hard-Burnished Surface

- Standard

- IS 2742 or Equivalent International Standard

About Asbestos Metallic Friction Sheet

High-Performance Friction Solution

Designed for heavy-duty applications, the Asbestos Metallic Friction Sheet combines durability with efficiency. Its robust metallic and wired construction ensures longevity even under high stress and extreme temperature conditions, while the oil-proof characteristic enhances performance consistency across various environments. Applications range from heavy vehicles to industrial equipment.

Customization and Versatility

With thicknesses from 3 mm to 25 mm and customizable sheet sizes, this friction material meets diverse operational needs. Whether for standard or specialized requirements, it can be supplied in sheets and cut to exact dimensions, ensuring a tailored fit for drum or disc brake systems. Both riveted and bonded mounting options are available for simplified installation.

FAQ's of Asbestos Metallic Friction Sheet:

Q: How is the Asbestos Metallic Friction Sheet typically installed?

A: The friction sheet can be mounted using either riveted or bonded techniques, depending on the application requirements and brake system design. Both methods provide strong, secure fixes for reliable operation.Q: What benefits does the metallic wire reinforcement provide?

A: Interwoven metallic wires and copper or brass mesh reinforcement enhance structural integrity, improve heat dissipation, and boost wear resistance, resulting in greater durability and consistent performance under demanding conditions.Q: Where can these friction sheets be used?

A: They are widely used in heavy vehicles (such as trucks and buses), industrial machinery, winches, and elevators, particularly for drum and disc brake systems that demand high reliability and longevity.Q: What is the process for ordering custom-sized sheets?

A: Customers can request customization by specifying their required sheet sizes. The manufacturer offers cutting services to ensure each order meets precise operational dimensions and specifications.Q: When should I choose this friction sheet over non-metallic alternatives?

A: Choose this sheet when your application involves high temperatures, heavy loads, oil exposure, or requires superior fade resistance and longevity. It excels in harsh environments where standard non-metallic sheets might underperform.Q: What are the main advantages of its high-temperature resistance?

A: Withstanding temperatures up to 350C, these sheets provide stable friction and minimal fade during prolonged operation, which is essential for safety and performance in heavy-duty braking scenarios.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Brake lining Category

Metallic Industrial Roll Brake Liner

Minimum Order Quantity : 1 Unit

Pattern Material : Other, Steel Backing with Sintered Friction Material

Usage & Applications : Steel Rolling Mills, Paper Mills, Textile Machines, HeavyDuty Industrial Equipment

Features : High Durability, Heat & Wear Resistant, Long Service Life, Stable Friction Coefficient

Standard : IS 11852 / OEM Equivalent

Noise Level : Low

Industrial friction sheet

Minimum Order Quantity : 1 Sheet

Pattern Material : Other, Friction Grade Compounds

Usage & Applications : Industrial clutches, brake linings, heavy machinery, cranes, elevators, hoists, and presses

Features : High Friction Coefficient, Wear Resistant, Durable, Oil Resistant, Heat Resistant

Standard : IS 2742, OEM Standards

Noise Level : Low Noise Operation

Asbestos Metallic Friction Liner Pad

Minimum Order Quantity : 1 Number

Pattern Material : Other, Asbestos & Metal Blend

Usage & Applications : Automotive, Industrial Machinery, Heavy Vehicles

Features : Heat Resistant, High Strength, Durable, Excellent Friction Properties

Standard : IS 2742 Certified

Noise Level : Low Noise Operation

Non Asbestos Brake Liner

Minimum Order Quantity : 1 Number

Pattern Material : Other, Organic Fibre with Resins

Usage & Applications : Automobile, Trucks, Buses, Commercial Vehicles

Features : High Durability, Heat Resistant, Eco Friendly, Long Life

Standard : OEM/IS:2742

Noise Level : Low

|

FIRETEX PROTECTIVE TECHNOLOGIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry