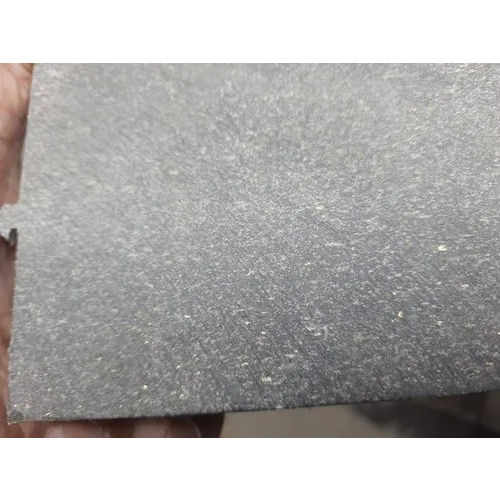

Non Asbestos Brake Lining

Non Asbestos Brake Lining Specification

- Usage & Applications

- Automotive, Industrial Machinery, Heavy Duty Vehicles

- Mounting Type

- Riveted or Bonded

- Features

- High friction coefficient, Asbestos-free, Environment-friendly, High temperature resistance

- Part Type

- Lining

- Noise Level

- Low

- Brake Type

- Drum Brake

- Size

- 200 mm x 20 mm x 6 mm

- Material

- Non Asbestos Organic

- Pattern Material

- Composite Fiber Blend

- Surface Finish

- Smooth

- Standard

- IS 11852 / OEM Equivalent

- Operating Temperature

- Up to 400C continuous

- Density

- 1.95 g/cm

- Thickness Range

- 6 mm to 25 mm

- Hardness

- 80 90 Shore D

- Pack Type

- Box / Carton Packaging

- Resistance

- Oil, Water, Heat and Dust resistant

- Color

- Brown

- Coefficient of Friction

- 0.36 0.45 (stable)

- Length

- 305 mm (standard); available in custom lengths

About Non Asbestos Brake Lining

Primary Advantages & Diverse Applications

Our Non Asbestos Brake Lining offers high friction performance, making it perfect for pivotal roles in automotive, industrial machinery, and heavy-duty vehicles. With a lustrous, smooth finish and stable operation under high temperatures, its kingly construction delivers unmatched reliability. Its highly customizable in length and fits diverse drum brakes, providing vital stopping power on critical surfaces. This environment-friendly lining, adhering to stringent IS 11852 standards, ensures safety and longevity across all commercial and industrial settings.

Packaging, Market & Delivery Details

Rely on secure shipping as our brake linings are boxed or cartoned to ensure product integrity. The main domestic market is India, catered by an extensive network of manufacturer, supplier, and trader partnerships. Custom length and configuration requests are accommodated with prompt estimate of expenditure and a short delivery time. Packaging is meticulously designed to minimize transit risk, with a focus on guaranteeing the product reaches your facility safely and efficiently, ready for installation.

FAQs of Non Asbestos Brake Lining:

Q: How does the non asbestos brake lining withstand heat during heavy usage?

A: This brake lining is engineered to operate continuously at temperatures up to 400C, maintaining its stability and effectiveness under high thermal conditions, ensuring safety and longevity in demanding applications.Q: What benefits does a non asbestos organic lining provide over traditional asbestos linings?

A: Non asbestos linings are environment-friendly and safe, producing low dust and significantly reducing health risks. With a stable friction coefficient, high durability, and excellent resistance to oil, water, and dust, they meet modern industry needs without compromising performance.Q: When should I consider customizing the brake linings size or length?

A: Custom lengths and sizes are recommended when your application involves unique drum brake dimensions or machinery that deviates from standard specifications, ensuring a perfect fit and optimal performance.Q: Where can these brake linings be applied?

A: These linings are suitable for automotive vehicles, industrial machinery, and heavy-duty vehicles where high performance and durability are critical, especially in drum brake systems.Q: What is the process for mounting the brake lining?

A: The linings can be mounted on brakes either through riveting or bonding, tailored according to your mechanical preference or specific operational requirements.Q: How is the packaging designed to ensure safe delivery?

A: Each lining is packaged in sturdy boxes or cartons, cushioned to protect against oil, water, heat, and dust. Secure shipping further ensures the product arrives intact and ready for immediate use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Brake lining Category

Heavy Commercial Vehicle Brake Lining

Minimum Order Quantity : 1 Unit

Material : Non Asbestos

Standard : High

Brake Type : Brake Shoes

Size : Standard

Part Type : Brake Lining

Industrial friction sheet

Minimum Order Quantity : 1 Sheet

Material : Asbestos Base

Standard : IS 2742, OEM Standards

Brake Type : Other

Size : Customized, available in various thicknesses and dimensions

Part Type : Friction Sheet

Asbestos Metallic Friction Liner Pad

Minimum Order Quantity : 1 Number

Material : Asbestos Metallic Composite

Standard : IS 2742 Certified

Brake Type : Other, Drum & Disc Brake Systems

Size : Customized sizes available

Part Type : Friction Liner Pad

Asbestos Metallic Friction Sheet

Minimum Order Quantity : 1 Sheet

Material : Asbestos with Interwoven Metallic Wires

Standard : IS 2742 or Equivalent International Standard

Brake Type : Other, Drum & Disc Brakes, Multiple Applications

Size : 1500 mm x 500 mm (custom sizes available)

Part Type : Friction Sheet / Lining Material

|

FIRETEX PROTECTIVE TECHNOLOGIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry